Circulating Subs

The Circulating Sub is designed to run immediately above or below the BHA. Activation is accomplished by dropping the S.S. Ball from the surface and applying pump pressure. This causes the shear pins in the sub to shear, allowing the Sleeve to drop from its primary position to its secondary position, opening the two sub ports which divert the flow to the annulus.

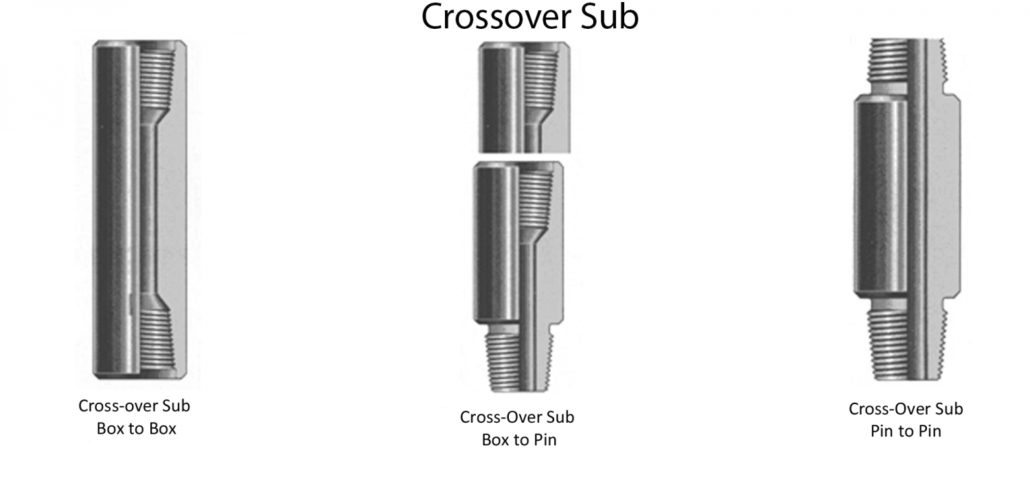

Crossover Subs

A crossover sub is used to crossover from one connection size to another or as the disposable component used to extend the connection life of a more expensive drill stem member.

Crossover subs are available with:

• box x pin

• box x box or

• pin x pin connections.

Crossover Subs are manufactured from 4145M or 4140HT alloy steel. The connections are protected by a phosphate surface coating that minimizes galling on initial make-up.

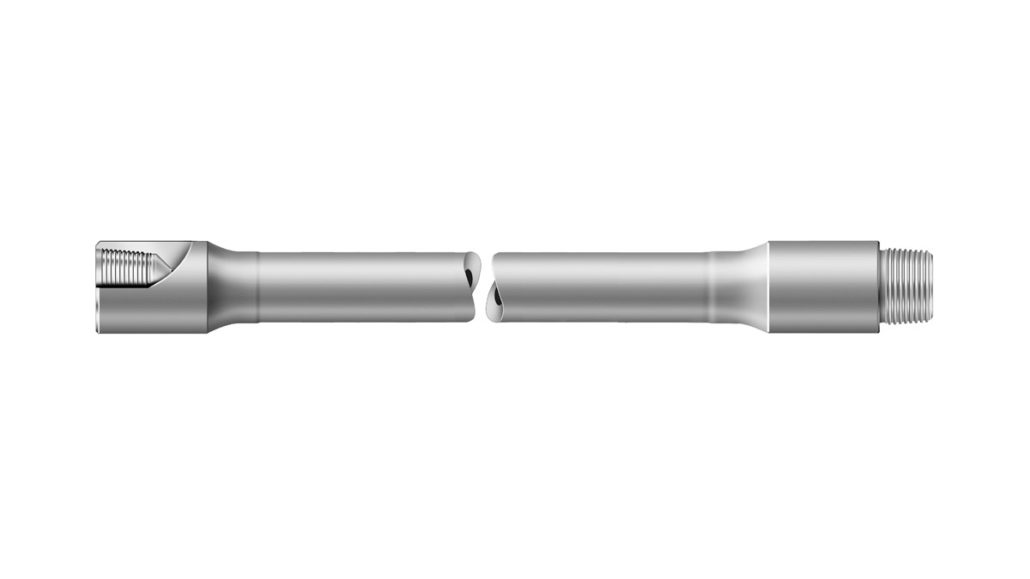

Drillable Lifting Sub

Drillable Lifting Subs are of one piece construction and manufactured from 4145M or 4140HT alloy steel. The Drillable Lifting Sub comes with an 18 degree tapered shoulder with a box up x pin down connection.

Available in all diameters and lengths. When ordering, please specify: • Drill Collar OD

• Tool Joint OD • DrillPipeOD • Bottom connection (pin end) • Top connection (box end) • Bore

Pressed or cast steel thread protectors

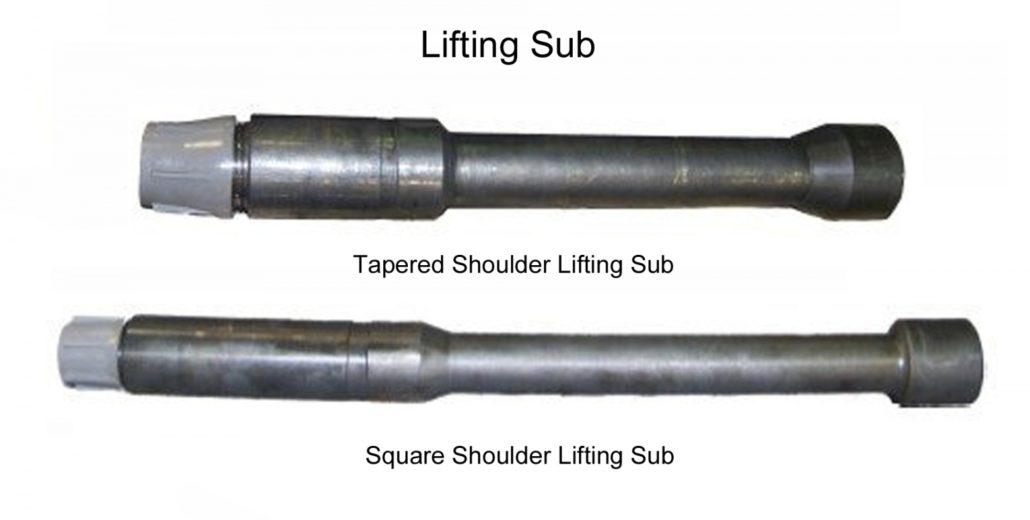

Drillable Pipe Pup Joints

Drilliable Pup Joints are short sections of well tubing made to API standards. The Drill Pipe Pup Joints are machined from integral bars of 4145H MOD Q&T (chromium molybdenum, manganese modification) alloy steel quenched and tempered to a hardness range of 285- 341 BHN (drill collar specs) Drill Pipe Pup joints are available in 5 feet, 10 feet, 15 feet and 20 feet lengths and can be ordered to match standard drill pipe dimensions.

*Welded pup joints are also available on request

When ordering, please specify:

• Overall length; 5 ft., 10 ft., 15 ft., 20 ft. or specific customer sizes • Drill pipe OD

• Tool Joint OD

• Tapered or square shoulder

• Drill pipe connection size & type

• Bor

• Pressed or cast steel thread protectors

Kelly Saver Sub

The Kelly Saver Sub is used to extend the life of the Kelly by taking the connection wear each time it is made up to a drill stem component. The saver sub connection is sacrificed because it can be easily repaired or inexpensively replaced.

The Kelly Saver Sub can be equipped with a rubber or brass protector to reduce BOP equipment and casing wear resulting from contact damage with the lower Kelly connection.

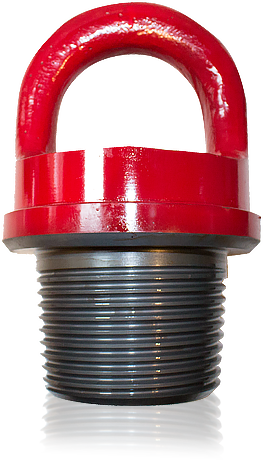

Lift Nubin

Lift nubbins are used for lifting tools and tubular products during manufacturing, shipping or at the rig site.

Lift nubbins are manufactured from steel castings with heavy-duty bails suitable for picking up and laying down all tools and tubulars.

All API connections are manufactured in accordance with API spec 7.

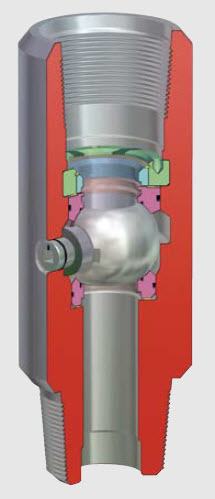

Kelly Valves

The Kelly Valve can be used as a dill pipe safety valve, Upper Kelly Valve, or Lower Kelly Valve.

As an Upper Kelly, the valve can be used to control blowout pressures by shutting off flow in the drill string at any time.

As a Lower Kelly, the valve can stop mud loss when the kelly is disconnected from the drill string.

Kelly Valves are manufactured from AISI 4140/4145 alloy steel and can be trimmed to standard or H2S.

The Kelly Valves can be provided as one or two piece construction.

Side Entry Saver Sub, Integral and Forged

Integral Side Entry subs are manufactured from 1 piece of AISI 4140/4145 alloy steel.

The side entry sub is manufactured with box by pin connections to match the drill pipe by an integral 2” 1502 union side outlet.