Adapter Spools

The Adapter Spool is provided in every size and pressure rating.

Our Adapter Spools with minimum length to provide adequate working space.

All Adapter Spools are manufactured per API 6A specs from 4130 H2S 75K material.

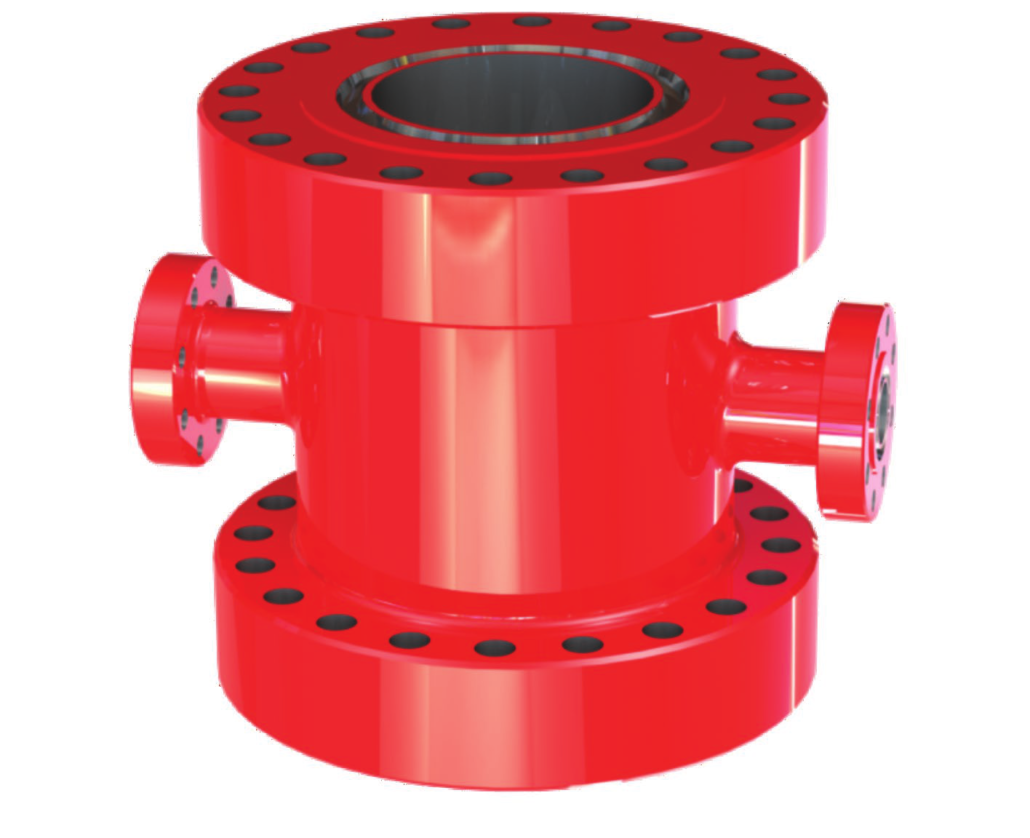

Drilling Spools

Drilling Spools are the parts which are often used in the oilfield when drilling, Drilling spools are designed to allow safe circulation of mud. Drilling spools usually have the same nominal end connections and the same nominal side outlet connections.

When ordering, please specify:

• Working Pressure • Type of top & bottom Connection • Type of side Connection • Length or height • Material Class

Spacer Spools

NERUM ENERGY Offers a wide range of sizes and capacities for

spacer spools Key Features :

• Flanged, studded, and hubbed ends available, in any combination

• Manufactured for any combination of size and pressure ratings

• Spacer Spools designed to minimize length while allowing sufficient clearance for wrenches or clamps, unless otherwise specified by the customer

• The standard design for Spacer Spools does not include outlets, although outlets can be added as specified

• Available for general service and sour service in compliance with any temperature rating and material requirements specified in API specification 6A

• Available with Stainless Steel 316L or Inconel 625 corrosion resistant alloy ring grooves Tap-end studs and nuts are normally provided with studded end connection.

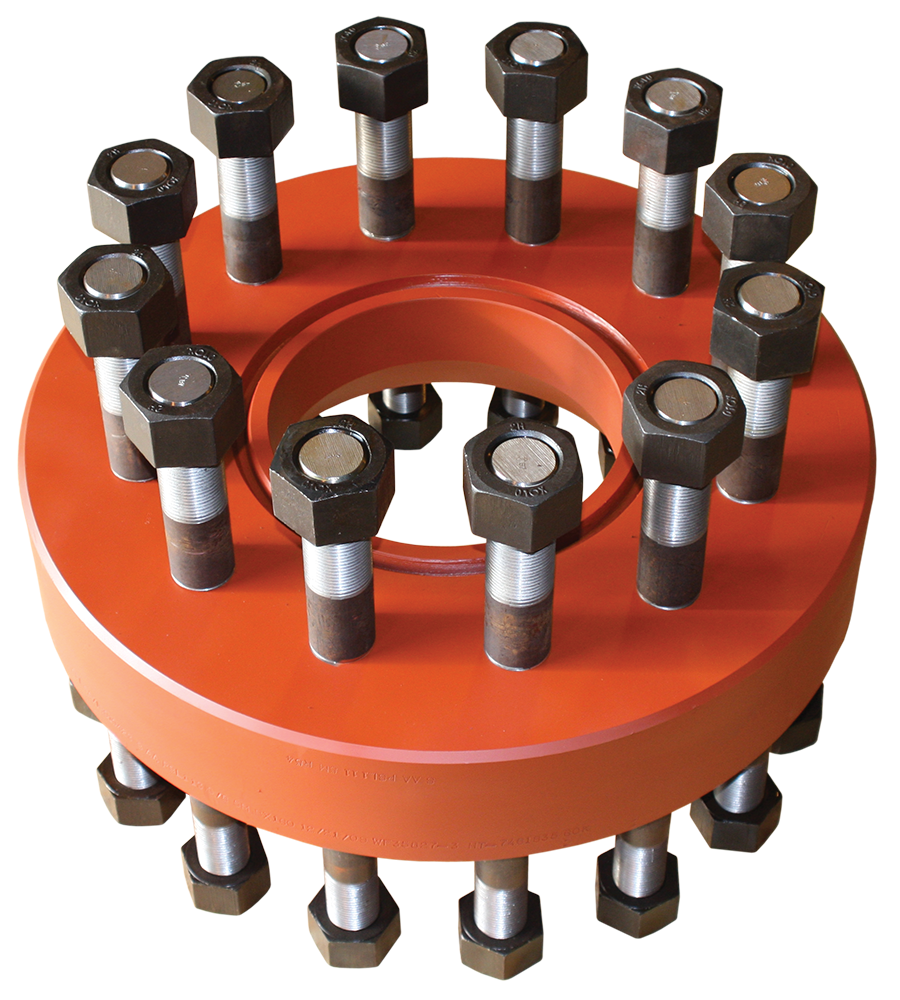

DSA (Double Studded Adapters)

DSA’s are a combination of flanges of different sizes and pressure ratings.

DSA is normally supplied along with appropriate size of studs with nuts duly fitted.

Adapter Flanges are used for transition in nominal size and/or pressure rating and where there is a restriction of space in the drill string.

They provide an ideal solution by hooking up two different equipments of different size and pressure rating. DSA’s are available as per customer specified thicknesses, consistent with design considerations.

Casing Heads

The lowest part of the wellhead that is almost always connected to the surface casing string, and provides a means of suspending and packing off the next casing string.

Providing attachment to the surface casing string through the type of bottom connection (Slip-on-weld, threaded, Sliploc), the casing head is typically qualified to withstand up to 10,000 psi working pressure.

It suspends the casing and packs off the next casing string while providing annular outlets, as well as supporting the BOP while drilling the remaining stages.

Base Plates

A load-supporting device attached to the starting casing head by means of either mechanical or permanent (welding) connection.

Designed to support up to 2,000,000 pounds (907,105 kg), FMC’s base plates fit almost all surface applications. Depending on your operation’s needs, both detachable and non-detachable options are available. For standard applications, detachable base plates have the following available:

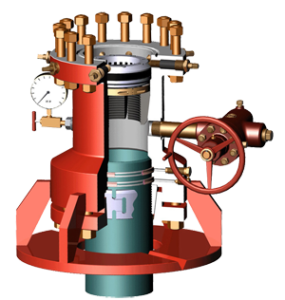

Tubing Heads

Equipment attached to the casing spool used to hang the tubing (smallest casing string) and seal the annulus between the tubing and casing.

The top spool on a wellhead assembly contains the highest pressure in the wellhead, and contains a load shoulder to hang the tubing hanger and tubing string. When the well is completed, the tree is installed on top of the head with a tubing head adapter. Providing a means to support and test the BOPs while completing the well, the tubing head is a necessary component when drilling and completing a well. The standard tubing head product line combines a straight- bore profile with a varied number of aligning pins, depending on the chosen model. FMC’s tubing heads eliminate the “wedge-locking” of the bowl protector, BOP test plugs, and tubing hangers. As additional advantages, valve removal (VR) threads are standard on all flanged or studded tubing head outlets, and if a 9” or larger top flange is required, the C-29 casing hanger can be used for casing-type completions.